Thermocouples |

Cerite® Thermocouple

Protection Tube Configurations

Cerite-II: Series #14-50

A heavy .58" thick wall of non-wetting Cerite is cast around a 1/2" NPT steel pipe to providea thermocouple protection tube in which the thermocouple elements can be replaced. Single thermocouple elements of 8,11, and 14 gauge, and duplex elements of 14 gauge wire can be used inside the Cerite-ll thermocouple protection tubes. A solid heat sink plug of graphite is cast into the bottom of this tube to provide good temperature response times. Available in lengths up to 48" long as standard, and also available in complete straight or angle thermocouple assemblies. |

Cerite-III: Series #15 -25

This unitized construction, combines a Cerite protection tube with an integral thermocouple element to form a complete thermocouple assembly. A .324" thick wall of non-wetting Cerite is cast around a 1/4" NPT steel pipe, which contains an integral 14 gauge ceramic insulated thermocouple element, and the assembly is provided with 36" of high temperature (13OO°F) fiberglass insulatedleads. The 1.187" overall diameter provides good temperature response times. This combination assembly is a very cost effective means of measuring molten aluminum process temperatures. Available in lengths up to 36”long. |

- Mechanical Strength: A thick wall of Cerite is cast around a steel pipe to provide both support for the castable material and to provide mechanical strength to resist breakage in process applications.

- Thermal Shock: Superior performance against other ceramic, silicon carbide, and refractory protection tubes. Does require some preheating and slow immersion into the molten metal as does other protection tubes.

- Temperature Response: Comparison testing against cast iron, silicon carbide, and other cast protection tubes resulted in comparable rates of temperature rise and response times.

- Non-Wetting Capabilities: Castable Cerite material was developed for molten aluminum applications and it has excellent non-wetting properties: it is erosion-resistant, and slag build-ups can be easily removed.

- Contamination: The high alumina content (85%) and a low content of silica (4%), make these Cerite protection tubes very low contaminating devices.

- Maximum Service Temperature: The castable Cerite material has a high temperature rating of 2800F (1538t), but its use ass thermocouple protection tube is generally limited to the temperature of molten aluminum ora maximum temperature of 1500F (81St).

- Useful Service Life: Side-by-side comparison testing of Cerite against all other protection tubes have resulted in equal or better service life. Actual service life will depend on the care, handling, and the allow the tubes are being used in, and no defined life expectancy can be stated.

- Mounting: All Cerife-ll protection tubes and unitized Cerite Ill thermocouple assemblies are provided with 1/2’NPT male pip connecting threads for ease of mounting without the need for expensive and cumbersome fittings as are required on silicon carbide and other assemblies. Installation and down-time is greatly reduced.

- Cost Effectiveness: The use of Cerite II thermocouple protecting tubes or the unitized Cerite Ill thermocouple assemblies provide a cost effective solution to measuring molten aluminum process temperatures. They have a lower, or comparable, initial cost than other tubes and assemblies. Their useful service life, mechanical strength, non-wetting properties, resistance to thermal shock, ease of mounting with reduced down-time, all combine to make the Cerite series of protection tubes a very cost effective tool in the molten aluminum process industry.

|

|

|

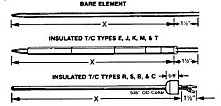

Straight Thermocouple Elements

|

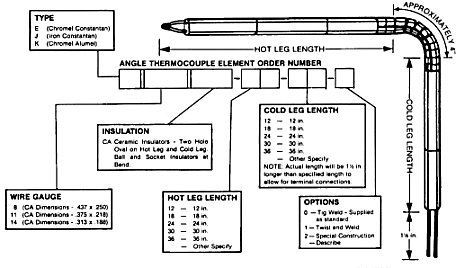

OPTIONS |

- Tig Weld Supplied As Standard

- Twist and Weld

- Special Construction - Describe

|

|

TYPE |

E (Chromel Constantan) 20 ga.

J (Iron Constantan) 8, 11, 14, 20 ga.

K (Chromel Alumel) 8, 11, 14, 20 ga.

T (CopperConstantan) 14, 20 ga.

M (Nickle - Nickle 18% Moly) 11, 18 ga.

R (Plat. - Plat. 13% RH) 24, 26 ga.

S (Plat. - Plat. 10% RH) 24, 26 ga.

B (Plat. 30% RH - Plat. 6% RH) 24 ga.

C (Tung. 5% Re - Tung. 26% Re) 24 ga. |

|

WIRE GAUGE |

8

11

14

18

20

2426 |

-.437 x .250

-.375 x .218

-.313 x .188

-.313 x .188

-.172 x .118

-.188 OD /w

.535 OD Collar

-.188 OD /w

.535 OD Collar |

|

INSULATION |

-- - No Insulator

(Do not use letter code)

CI - Ceramic Insulators

Two Hole Over

CD - Duplex Thermocouple

Type E, J, K, T, M Thermo-

couples supplied with

refractory insulators

- 2475°F max. temp.

Type R, S, B, C thermo-

couples supplied with

99.7% Alumina Insulators

- 3400°F max. temp.

|

|

LENGTH |

012 - 12 in.

018 - 18 in.

024 - 24 in.

030 - 30 in.

036 - 36 in.

- Other

Specify

Note: Actual

length will be

1½" longer

than specified

length to allow

for terminal

connectors. |

|

|

Angle Thermocouple Elements

|

|